Powder Metallurgy (PM) is an advanced manufacturing process used to create metal components from metal powders. It involves pressing metal powders into a desired shape (usually at room temperature), followed by heating (sintering) the compacted shape in a controlled atmosphere furnace. The process allows for the production of complex parts with precise dimensions and material properties.

🌟 Key Steps in Powder Metallurgy

Powder Production

Metal powders are produced using methods like atomization, reduction, electrolysis, or mechanical alloying. The size, shape, and composition of the powder significantly affect the properties of the final product.

Blending and Mixing

Different metal powders are blended with additives such as lubricants or alloying agents to ensure uniformity and facilitate pressing.

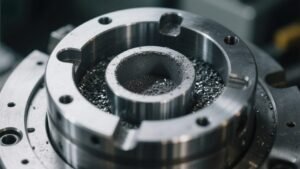

Compaction (Pressing)

The blended powder is compressed in a die under high pressure to form a “green compact.” This compact has the shape of the final product but is still fragile.

Sintering

The green compact is heated in a furnace to a temperature below the melting point of the main metal. This fuses the particles, improving strength and structural integrity.

Secondary Operations (Optional)

Depending on the application, the part may undergo additional processes like sizing, machining, steam treatment, infiltration, impregnation, or heat treatment.

Advantages of Powder Metallurgy

Material Efficiency: Near-net or net-shape production reduces waste.

Cost-Effective: Especially for high-volume production.

Design Flexibility: Capable of producing intricate and complex geometries.

Excellent Tolerances: Minimal post-machining required.

Porosity Control: Can produce both porous and fully dense materials.

Wide Material Range: Includes ferrous and non-ferrous metals, ceramics, and composites.

Applications of Powder Metallurgy

Powder metallurgy is widely used in:

Automotive industry: Gears, bushings, valve guides, structural parts

Aerospace: High-temperature components, filters

Medical: Dental implants, surgical tools

Tools and Hardware: Cutting tools, abrasives

Electronics: Magnetic and soft magnetic components

Powder Metallurgy is a versatile and sustainable manufacturing technology that enables high-precision, cost-effective production of metal parts with customized properties. It is ideal for industries that demand high-performance, lightweight, and complex-shaped components with minimal material loss.