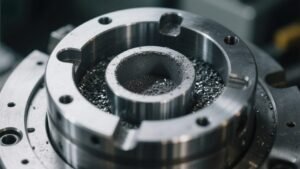

A sintering furnace is a specialized industrial furnace used to heat compacted metal or ceramic powders (known as “green parts”) to a temperature below their melting point, causing the particles to bond together into a solid, dense, and mechanically strong product. This process is a core step in Powder Metallurgy (PM).

Purpose of Sintering

Sintering transforms fragile, loosely compacted powder parts into rigid, high-strength components by promoting atomic diffusion between adjacent particles. It enhances:

Mechanical strength

Density

Electrical conductivity

Dimensional stability

Key Components of a Sintering Furnace

Heating Zone(s): Where the main sintering occurs. Temperatures typically range from 750°C to 1350°C for ferrous alloys.

Cooling Zone(s): Gradually reduces the temperature to avoid thermal shock or warping.

Controlled Atmosphere: Inert (e.g., nitrogen, argon) or reducing (e.g., hydrogen) gases prevent oxidation.

Conveyor or Mesh Belt System: Used in continuous furnaces to move parts steadily through each zone.

Insulation and Refractory Lining: Maintains temperature uniformity and energy efficiency.

Temperature & Process Control (PLC/SCADA): Ensures precise temperature profiles, atmosphere flow, and dwell time.

A sintering furnace is essential to the powder metallurgy process, enabling the production of strong, high-density components from metal powders. Through precise temperature and atmosphere control, it ensures that the sintered parts meet the demanding requirements of industries like automotive, aerospace, and medical.